Global Leading Solution Provider on HIP Materials & products

Pioneering spirit、The spirit of struggle 、The spirit of craftsmanship

CORE ADVANTAGE

Four core benefits

Comprehensive high-tech enterprise

Whole industry chain:Design, research and development, manufacturing, sales and after-sales service as a whole

A wide range of products in all sizes

Based on domestic and global research to develop the world's high-quality hot isostatic pressing products, breaking through and solving a series of hot isostatic pressing science and key engineering application problems

Located at a major transport hub

Jiaxing Port is located in the "one-hour traffic circle" between the southern wing of Shanghai, the northern coast of Hangzhou Bay and the surrounding cities of Shanghai, Hangzhou, Ningbo and Suzhou.

Advanced Materials

makes the world better.

Delivering cost-effective solutions

The core team has many doctors and masters in materials science, automation, machinery, metallurgy; engaged in hot isostatic pressing product development for many years, completed a number of national major product research projects

ABOUT US

About

Doevol (Hangzhou) Material &Technology Co., Ltd. is a comprehensive high-tech enterprise,It has the whole industry chain: design, research and development, manufacturing 、 sales,and after-sales service as a whole, relying on China Iron and Steel Research Institute and Beihang University, and cooperating with Central South University and Beihang University Hangzhou Innovation Research Institute, aiming to continuously improve products, update and iterate to better meet customer needs, based on domestic and global research to develop the world’s high-quality hot isostatic pressing products。

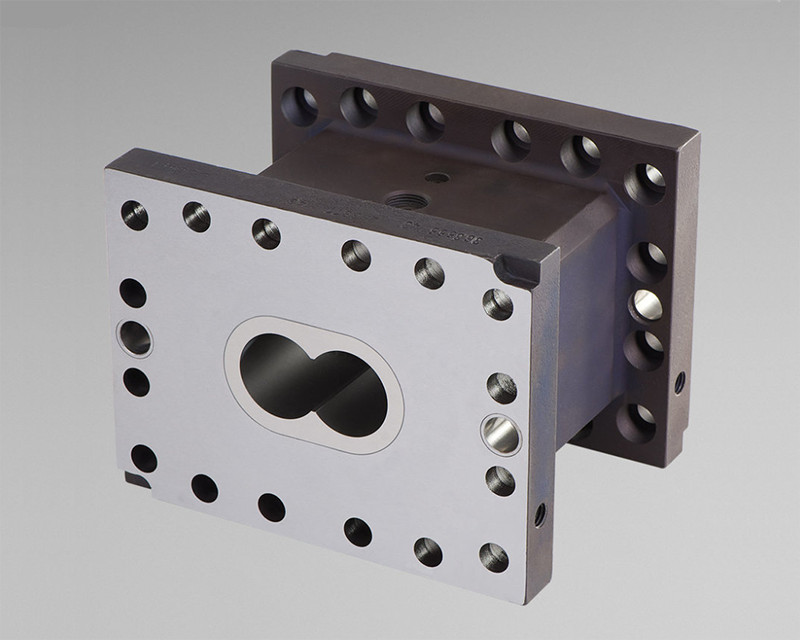

The factory is located in Binhai Business Park, Jiaxing Port District, Zhejiang Province, and settled as the winner of the 2021 Jiaxing Port District Innovation and Entrepreneurship Competition; With hot isostatic pressing advanced composite materials as the core, it provides cost-effective solutions for key metal wear parts in many industrial fields; R&D materials are widely used in new energy lithium battery slurry production lines, aerospace, intelligent manufacturing, petroleum and petrochemical, and deep-sea oil and gas resource development and other fields;

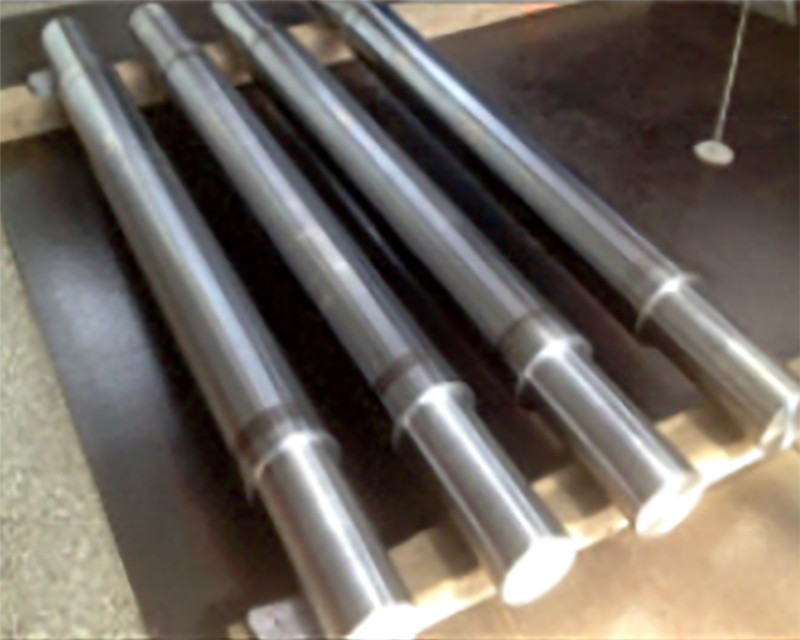

Has been successfully developed and mass-produced in the twin-screw granulation equipment, injection molding machine halogen-free field, composite rolls with high wear resistance, high corrosion resistance, high temperature resistance materials;

Is a global leader in hot isostatic materials and product solutions.

Product Centre

Product

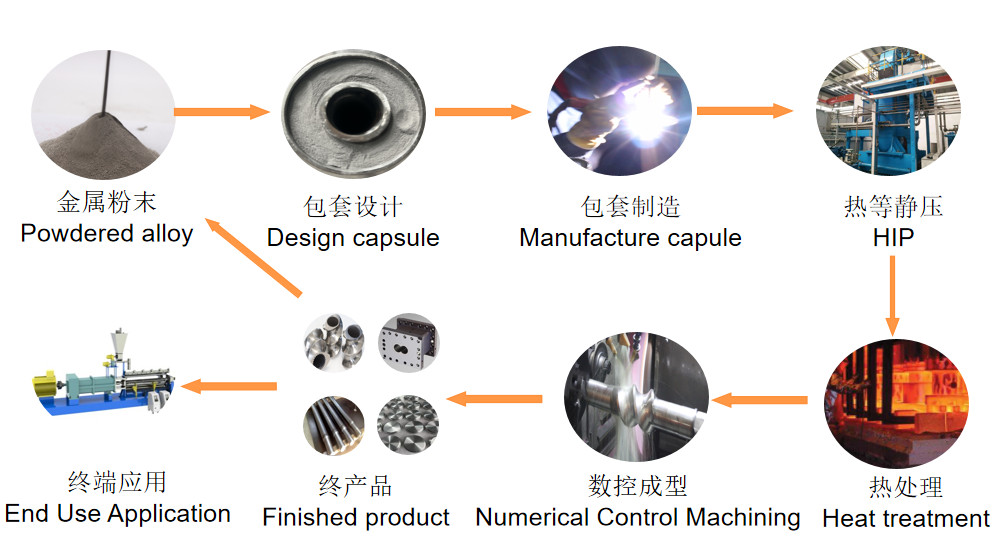

What is hot isostatic materials ?

Hot Isostatic Pressing (HIP) is a special heat treatment process for metallic or ceramic materials and is an important tool for the preparation of high performance materials. The process technology can be used for powder metallurgy molding or for densification of castings (titanium alloys, high-temperature alloys, aluminum alloys and other loose shrinkage castings) after molding. After the hot isostatic treatment, the wear resistance, corrosion resistance and mechanical properties of the material will be greatly improved, and the fatigue life can be increased by 10~100 times.

Processing characteristics:

High temperature Up to 2000°C

High pressure Up to 200 MPa

Isostatic pressure Using an inert gas as the pressure transfer medium, the same pressure is applied uniformly to the surface of the part from all directions.

Main application material systems:

High temperature alloys, titanium alloys, aluminum alloys, copper alloys, refractory metals, hard alloys, stainless steel, corrosion resistant alloys, ceramics, composite materials, electronic materials, functional materials, etc.

Why use hot isostatic materials?

Greatly improves the mechanical properties of the material, increasing its fatigue life by 10 to 100 times

Any material made of products have a certain service life, can not be used indefinitely, the root cause of material failure there are two, one is the internal structure of the material changes, that is, due to the interference of the external environment to change the composition of the material, the new composition can not reach the appropriate performance, the material then failed; another more common reason is that, due to the material internal residual impurities, small cracks, holes, etc., the formation of a sudden change in performance, we call it a material defect, in the working state of the material, for example, when the material is subjected to high temperature cycles and stress cycles, the location of the sudden change in performance will produce a stress concentration effect, and eventually the point produces fatigue. Another more common reason is that, due to residual impurities, small cracks, holes, etc., the formation of a sudden change in performance, we call it a material defect, in the working condition of the material, for example, when the material is subjected to high temperature cycles and stress cycles, the location of the sudden change in performance will produce a stress concentration effect, and eventually fatigue diffusion at the point, so that the material fracture failure. Any of the current conventional molding methods cannot directly eliminate the residual defects inside the material, and all require subsequent treatment processing.

hot isostatic materials, as a special metal heat treatment process, is currently the most effective heat treatment method for eliminating internal defects in materials, and the material forming method that results in the least amount of internal defects in materials. Therefore, hot isostatic pressing is a routine processing step for important critical parts in various fields worldwide.

products

Main Products

NEWS

News

New product release| HIPEX new product third-generation hot isostatic pressing system HIPEX500 released

During the meeting, Mr. Lv Zhoujin, Chairman and General Manager of HIPEX Technology Co., Ltd., released the new HIPEX500 equipment of the third-generation hot isostatic pressing system independently developed by HIPEX, and introduced in detail the application of hot isostatic pressing technology and the development and manufacturing development process of…

Doevol Materials|The first hot isostatic pressing conference ended successfully|Hengxin entrepreneurship and forged ahead

From March 22nd to March 24th, the first hot isostatic pressing user conference & the second commercial heat treatment conference was held in Courtyard by Marriott Suzhou HEJING, with more than 160 enterprises and hundreds of representatives from the application industry and service market, Doevol Materials was specially invited to…

Doevol Materials|24 production is uninterrupted

At the beginning of the recovery of all things and summer, Doevol Materials ushered in the important day of the second anniversary of its establishment on May 10, in the first two years, despite many difficulties, but we still achieved steady growth in sales, every achievement is inseparable from everyone’s…

QUINTUS Hot Isostatic Pressing

Each QUINTUS® hot isostatic press features a cylindrical high-pressure vessel and yoke frame structure with a high-strength prestressed cold-rolled spring wire winding design. Prestressing allows the pressure vessel wall to retain residual compressive stress even at maximum working pressure to eliminate tensile loads and prevent crack propagation and brittle failure.